In the age of smart transformation and digitalization, intelligent transformation and digital upgrades are the inevitable paths for achieving high-quality transformations in manufacturing enterprises. How should enterprises

undertake intelligent transformation and digital upgrades? Faced with this imperative question, Dreame (Suzhou) Co., Ltd. has provided a comprehensive answer.

In 2021, the manufacturing sector in Jiangsu Province

contributed over 4 trillion yuan to the GDP, representing 35.8% of the total, the highest proportion in China. Additionally, the digital economy scale of Jiangsu Province accounted for 11.8% of the national total, maintaining

its position as the leader in integrated development of digital transformation and industrial upgrade for seven consecutive years.

The data highlights Jiangsu Province's dual identity as both an economic powerhouse

and a leading province in digital technology. Recognizing its status as a manufacturing hub, the Jiangsu Provincial government has issued the Three-Year Action Plan for Intelligent Transformation and Digitalization of the

Manufacturing Industry (2022–2024). This plan aims to support industrial enterprises in their intelligent and digital transformation efforts while providing targeted assistance for the transformation of small and medium-sized

businesses.

Debut of Dreame

Dreame Technology is an innovative tech company with a strong focus on smart home appliances. Operating globally, its presence spans over 100 countries and regions, including China, the United States, Russia, and Germany. The company is dedicated to developing cutting-edge smart home appliance technology and has been actively enhancing its digital capabilities. In 2021, it underwent a comprehensive transformation of its production line, optimizing its information system architecture and achieving digital upgrades across various operations such as production, warehousing, and logistics. Additionally, Dreame Technology implemented Ruijie wireless solutions in its headquarters, warehouse supply chain, and production facilities. Ruijie Networks established a more stable, reliable, and intelligent wireless network for Dreame to accelerate its overall digital transformation.

Production Base: Seamless Roaming of AGVs and Zero Packet Loss During Movement

Dreame's products are distributed from their supply chain base to customers across the country. Given the high product quality, strong demand, and large shipment volume, Dreame introduced the Warehouse Management System (WMS) in 2022. This system simplifies

the picking process for workers by utilizing a barcode scanner. Workers only need to scan the shipping order using the scanner and then access the inventory management system on their computers to locate the product accurately.

This streamlined the picking process.

In the supply chain warehouse, there are over 70 employees equipped with barcode scanners who move around the factory floor. The warehouse

handles over 20,000 orders daily, resulting in approximately 200,000 barcode scans. The high frequency of barcode scanning places significant demands on the network infrastructure. Dreame's supply chain base spans an area

of 8,000 square meters with a height of 6 meters and is filled with iron shelves, which block signals and pose challenges for wireless network coverage.

Ruijie's industrial wireless seamless roaming technology

has established a high-quality network for Dreame. This technology allows Dreame's barcode scanners to collect data in milliseconds. Additionally, the seamless wireless coverage provided by Ruijie ensures stable and real-time

operation of the barcode scanners in every corner of the supply chain base. This helps Dreame maintain uninterrupted business operations.

Supply Chain Base: High-quality Wireless Network Without Coverage Holes

Dreame's products are distributed from their supply chain base to customers across the country. Given the high product quality, strong demand, and large shipment volume, Dreame introduced the Warehouse Management System (WMS)

in 2022. This system simplifies the picking process for workers by utilizing a barcode scanner. Workers only need to scan the shipping order using the scanner and then access the inventory management system on their computers

to locate the product accurately. This streamlined the picking process.

In the supply chain warehouse, there are over 70 employees equipped with barcode scanners who move around the factory floor. The warehouse

handles over 20,000 orders daily, resulting in approximately 200,000 barcode scans. The high frequency of barcode scanning places significant demands on the network infrastructure. Dreame's supply chain base spans an area

of 8,000 square meters with a height of 6 meters and is filled with iron shelves, which block signals and pose challenges for wireless network coverage.

Ruijie's industrial wireless seamless roaming technology

has established a high-quality network for Dreame. This technology allows Dreame's barcode scanners to collect data in milliseconds. Additionally, the seamless wireless coverage provided by Ruijie ensures stable and real-time

operation of the barcode scanners in every corner of the supply chain base. This helps Dreame maintain uninterrupted business operations.

R&D and Office Headquarters: Easy O&M and Efficient Network Operation

Dreame's research and office headquarters have also been upgraded to the Ruijie wireless network. The company's office area is spread across 10 buildings, with three of them specifically designated for research and development

purposes. These R&D office areas are designed in an open-plan layout, accommodating over a hundred R&D personnel on each floor and equipped with nearly five hundred terminal devices. The primary focus of the R&D areas is

to support office operations and conduct testing for cleaning robots.

Before the robot vacuum cleaners are shipped from the factory, the R&D team conducts multiple tests to ensure product quality. During testing,

the robot connects to the wireless network to transmit test data to the mobile phone of the R&D personnel. However, as the robot only supports the 2.4 GHz band and there are only three non-interfering channels in this band,

adjacent access points (APs) cannot be deployed on the same channel. Therefore, before testing the robots, the O&M personnel need to manually plan the network channels and choose non-overlapping channels for adjacent APs.

They also need to adjust the power manually. If the power is set too low, the wireless signal will be weak; if it is set too high, it will cause interference with surrounding APs. The entire process of adjusting the channels

and power takes a day.

After the network upgrade, O&M personnel only need to log in to Ruijie WIS cloud management network and perform one-click network optimization. The Ruijie wireless solution then automatically

plans a channel solution with high transmission efficiency and the lowest interference level for the entire network. O&M personnel only need to wait for 30 minutes, which greatly simplifies network management and improves

O&M efficiency.

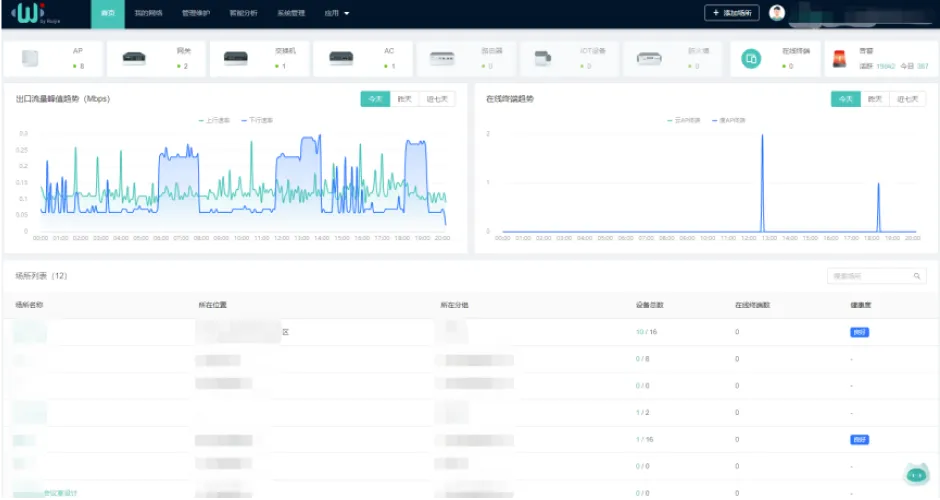

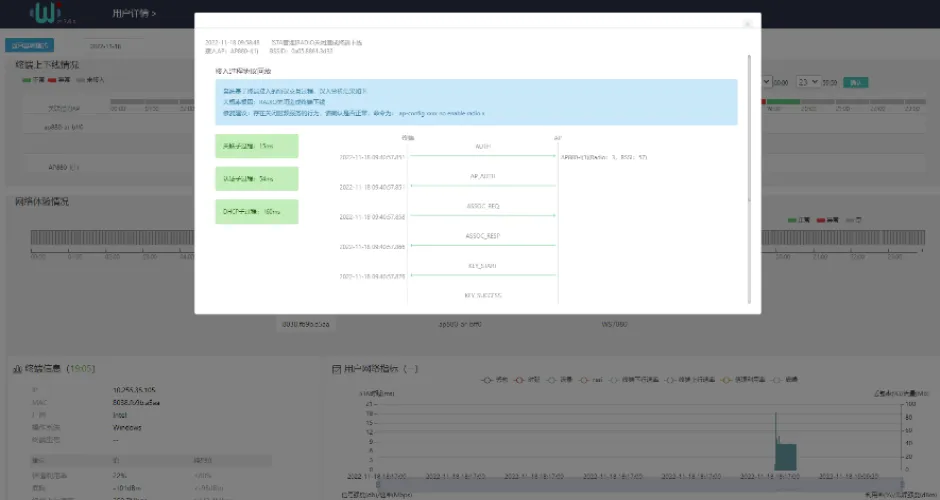

The changes in O&M work go beyond this. Before the network upgrade, all wireless devices of Dreame were not centrally managed online. O&M personnel received a large number of fault reports by phone. They had to go to the site to solve the fault, and it took a day to find the fault and solve the fault. After the upgrade, the WIS cloud network management platform implements unified management of all APs on the network. After receiving a fault report, O&M personnel only need to log in to the WIS cloud network management platform to view the terminal history, obtain the complete fault information, find the fault cause in one minute, and quickly view the solution. The WIS cloud network management platform makes O&M easier and networks more efficient.

- Screenshot of the Home Page on the WIS Cloud Network Management Platform

- Screenshots of STA Diagnosis on the WIS Cloud Network Management Platform

Ruijie's wireless solution has created a stable, reliable, and intelligent wireless network for Dreame in production, warehousing, and office settings. This has enhanced Dreame's smart manufacturing and innovative research capabilities, driving high-quality development and the transformation of technological achievements into productive and high-quality products. It enables Dreame to deliver superior smart home appliances to customers.

Related Products

Scenario Innovation,Drives the Digital Future

Learn more about Ruijie